Single-cylinder Hydraulic Cone Crusher

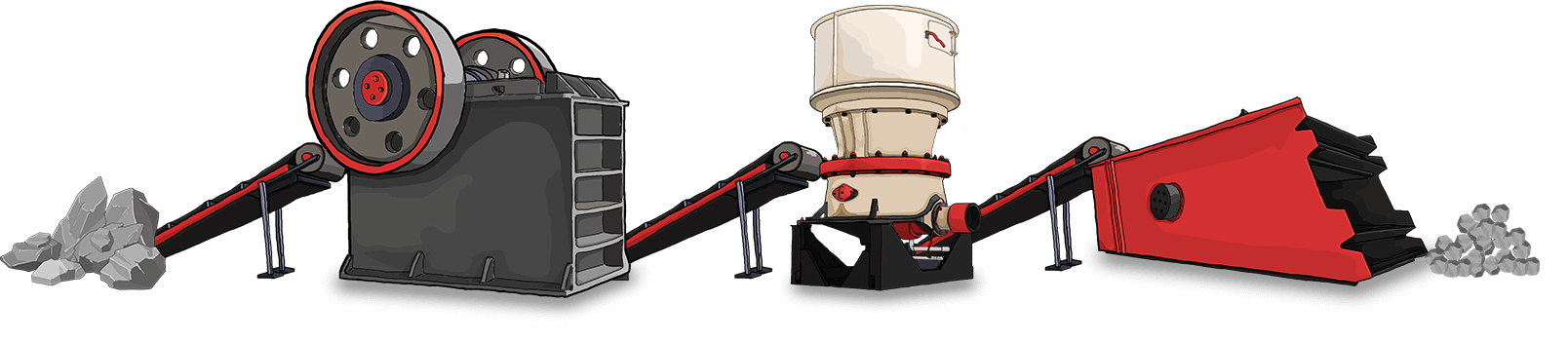

SC(S) series single-cylinder hydraulic cone crusher is developed with the world's advanced crushing technology, integrating mechanical, hydraulic, electrical, intelligent control and other technologies. The new crusher structure, optimized laminated crushing chamber and fully intelligent automatic control system make the SC(S) series single-cylinder hydraulic cone crusher have the performance characteristics that are not available in the traditional cone crusher.

Brief In Single-cylinder Hydraulic Cone Crusher

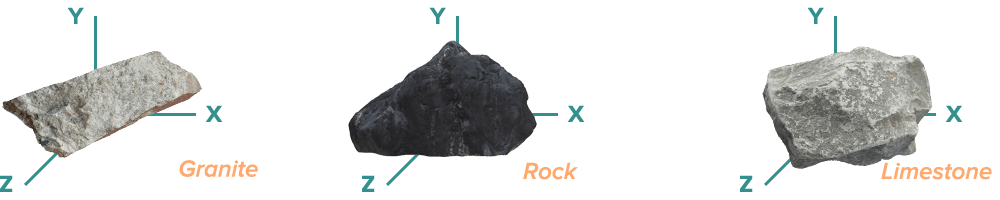

The single-cylinder hydraulic cone crusher is widely used in metallurgy, construction, hydropower, transportation, chemical industry, building materials industry. It is suitable for crushing various ores and rocks with hard and medium hardness (intermediate, fine and ultrafine crushing process), such as river pebble, granite, basalt, iron ore, limestone, Quartz stone, diabase, iron ore, gold ore, copper ore, etc.

The hydraulic cone crusher adopts the unique crushing cavity shape and the laminating crushing principle to produce the crushing effect between the particles, so that the proportion of the cube in the finished product is obviously increased, the needle-like stones are reduced, and the particle size is more uniform. Therefore, it is highly recognized and favored by users in the industry, especially by metal mines and construction sandstone processing plants, and has become one of the hot sale devices in the industry.