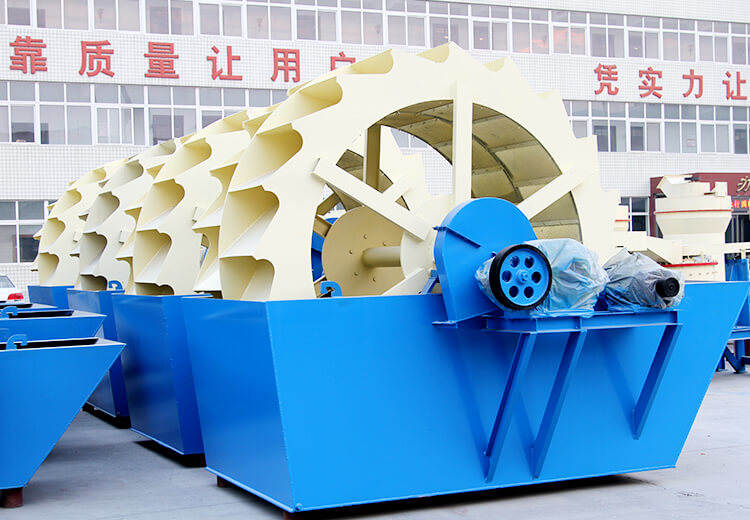

Sand Washing Machine

The sand washing machine adopts advanced technology and combines the actual situation of sand and gravel industry to become high-efficiency sand washing equipment. It has reasonable structure, large output, and less sand loss during sand washing, especially its transmission part is isolated from water and sand, so the failure rate is much lower than the current common sand washing machine. It is the choice for upgrading the sand washing industry.

Brief In Sand Washing Machine

The FTM sand washing machine is made of special materials, which can resist abrasion and corrosion, so that it can operate normally under any harsh environment and greatly prolong its service life. The sand washer has a diameter of 2200-3500mm and a production capacity of 15-200t/h. It is widely used in construction sites, sand gravel fields, glass factories, power stations, concrete prefabricated stones and electrical fields.

Increasing the output of sand washing machines has always been the focus of users. In order to meet the needs of users, Henan Fote Heavy Machinery Co., Ltd. has made appropriate adjustments to the sand washing machine, which has achieved the high output requirements of the sand washing machine and improved the quality of the sand stone. In addition, if the user wants to keep the high output of the sand washing machine at all times, it is necessary to carry out regular maintenance work on the sand washing machine to ensure the smooth running of the sand washing machine.