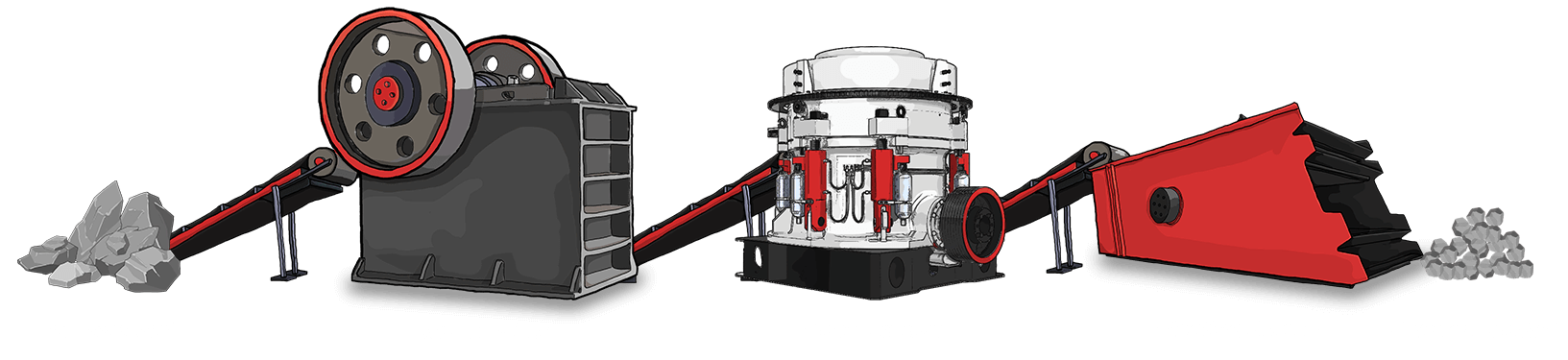

Cone Crusher

This series of crusher is divided into three types: coarse cone crusher, medium cone crusher and fine cone crusher. The standard type is suitable for medium crushing, the medium type is suitable for fine crushing, and the short head type is suitable for fine crushing . According to different principles, it can be divided into hydraulic cone crusher, single-cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher, compound cone crusher, and spring cone crusher, which can be purchased according to their own needs .

Brief In Cone Crusher

This series of crusher is suitable for crushing various ores and rocks with medium hardness and above. It has the characteristics of reliable structure, high production efficiency, convenient adjustment, and economical use. The spring safety system is an overload protection device, which can make the foreign iron block pass through the crushing chamber without jeopardizing the machine, and adopts two kinds of sealing forms of dry oil or water to isolate the stone powder from the lubrication to ensure reliable operation.

During operation, the rotation of the motor is rotated by a pulley or a coupling, a cone crusher drive shaft and a cone of the cone crusher under the urging of the eccentric sleeve. Therefore, the broken wall of the crushing cone is close to and sometimes leaves the surface of the shackle wall fixed on the adjusting sleeve, so that the ore is continuously subjected to impact, extrusion and bending in the crushing chamber to realize the crushing of the ore.